Case study #103: Chhabra Thermal Power Plant, Rajasthan

Water metering without the risk of leakages and pressure drop.

Adept helps a leading thermal power plant to achieve it successfully.

Fixed type Ultrasonic & Electromagnetic Flowmeters from Adept help in precise flow measurement for critical processes.

In a thermal power station, several water flow circuits are involved which require permanent metering as well as temporary spot measurements. At Chhabra Power Plant, RVUN was looking for a solution for such flow metering requirements. They also required Flowmeters for the ETP.

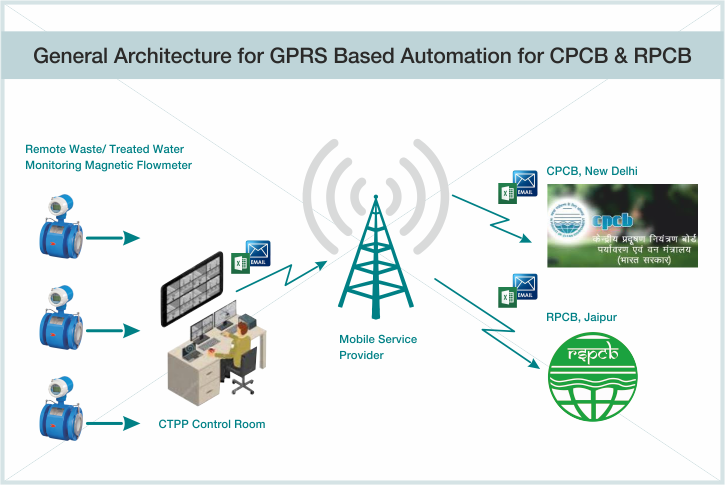

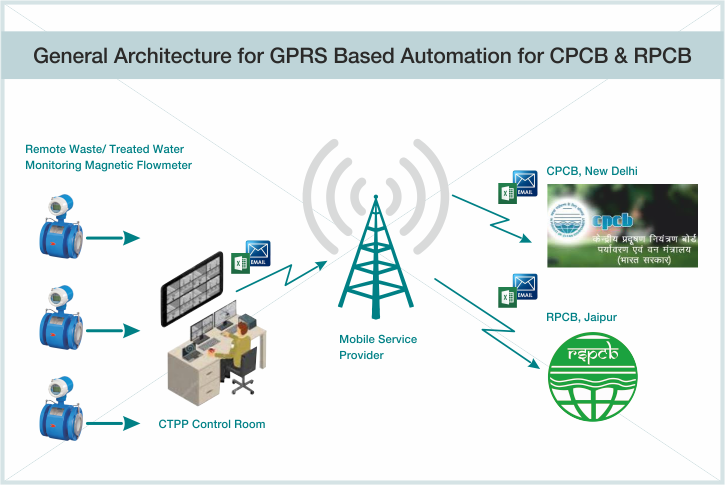

Ability to handle the project on a turnkey basis and proven experience were the main criteria for the selection of the instrumentation partner. Based on these expectations, Adept was their obvious choice, considering our ability to provide not only the Flowmeters, but also Automation, RPCB & CPCB connectivity support and SCADA connectivity support.

Challenges

At CTPP, the requirement of Flowmeters existed in two areas, viz.

![]() Main Power Plant

Main Power Plant

![]() Effluent Treatment Plant (ETP)

Effluent Treatment Plant (ETP)

Main Power Plant

Thermal power stations generate electricity by heating water to generate steam, which in turn, drive turbines and generators. In this process, there are several flow circuits which require constant flow monitoring. This necessitates installing Flowmeters for permanent metering as well as for temporary spot measurements. Water flows at a very high speed through the pipelines of the power plant. This imposes limitations on the use of inline Fowmeters due to the possibility of leakages and also the inline device disturbs the flow and can cause pressure drops. Another challenge is

Effluent Treatment Plant (ETP)

CTPP also required suitable Flowmeters for the measurement of flow at critical locations such as ETP, clear water line and horticulture water lines. Being a large power plant, high amount of effluents are generated during various processes which are treated through ETP for reuse or recycling of water. The flow of effluents and water requires to be carefully monitored at several steps in ETP. Accuracy of the flow data is highly important, which is required to be sent to RPCB & CPCB.

Solution

For Main Power Plant Water Metering

After thoroughly evaluating the requirement of flow metering at various stages at CTPP, we suggested a combination of non-contact, clamp-on, fixed type Ultrasonic and Electromagnetic Flowmeters. Purified water, due to absence of minerals, does not have electrical conductivity and thus eliminates the possibility of using electromagnetic Flowmeters.This comprises 16 nos. Ultrasonic Flowmeters model 6710 and 4 nos. Full-bore Electromagnetic Flowmeters model 6410 of various sizes ranging from 50 mm to 700 mm.The project was handled on a turnkey basis comprising supply of Flowmeters, installation & commissioning, and providing after-sales service for one year. The complete scope also included supply of other required material such as cables, JBs, field canopy, as well as carrying out allied work such as laying cables for a stretch of 12 km, excavation and civil work.

Typical applications of UFM 6710 Clamp-on Flowmeters

![]() Feed water, cooling water and condensate flow metering

Feed water, cooling water and condensate flow metering

![]() Pump, valve and inline Flowmeter performance verification

Pump, valve and inline Flowmeter performance verification

![]() Leakage and blockage detection

Leakage and blockage detection

![]() Metering of fly ash disposal lines

Metering of fly ash disposal lines

![]() Heavy fuel oil metering

Heavy fuel oil metering

![]() Hot well make-up line

Hot well make-up line

![]() Hot well make-up discharge line

Hot well make-up discharge line

![]() Make-up line of DM CW overhead panel

Make-up line of DM CW overhead panel

![]() DM water transfer pumps at discharge line

DM water transfer pumps at discharge line

![]() Boiler feed pumps at discharge line

Boiler feed pumps at discharge line

![]() Forebay make-up line

Forebay make-up line

![]() Raw water pump house

Raw water pump house

For Effluent Treatment Plant (ETP)

We supplied, 4 nos. full bore type Electromagnetic Flowmeters model 6410 for ETP and horticulture lines. The work also involved providing complete automation solution and IoT gateway with the help of SCADA for ensuring connectivity to RPCB & CPCB.

Benefits

With the help of most relevant solutions from Adept, CTPP could fulfil their expectations while achieving several objectives.

Installing inline Flowmeter necessitates boring of pipe. This increases the possible risk of leakage of pipes due to high pressure in feed water pipes. Moreover, any inline device causes pressure drops and affects the flow of the medium. To avert these risks, Adept recommended Ultrasonic Flowmeters UFM 6710. The sensors of the UFM 6710 are clamped onto the outside of pipes and hence, there is no pressure drop and no risk of leakage at any time.

In order to avoid corrosion, feed water used in steam boilers of thermal power stations is highly purified. Due to its high purification level, it becomes an electrical insulator eliminating the possibility of measuring flow with electromagnetic meters. By employing ultrasonic technology to determine flow rates, the UFM 6710 clamp-on meters can measure the flow of liquids regardless of their electric conductivity.

The installation of inline Flowmeters requires pipes to be cut, which in turn, requires shutdown of single systems or sometimes the entire plant. As the sensors of the UFM 6710 Ultrasonic Flowmeters are clamped onto the outside of pipes, there is no need to cut them and therefore, no interruption of the flow.

The flexibility offered by our portable and fixed-installation Flowmeters enables them to be used at different areas of a power station, for different liquids and on pipes of almost every common material and diameters from 10 mm to 4570 mm. Due to the high temperature resistance of our clamp-on sensors, Adept Flowmeters can also be used on pipes with temperatures of up to 250oC, which makes them suitable for use on hot water and condensate pipelines.

Due to the GSM connectivity and SCADA support, Adept Flowmeters can be easily integrated with the centralised system.

Rajasthan is India’s largest state by area and is well-known for its forts, havelis, Thar desert and it is also home to three national tiger reserves. The state has acquired significance because of growing tourism and rapid industrialisation, and is experiencing a surge in demand for electricity. To cope up with this demand, Rajasthan Rajya Vidyut Utpadan Nigam Limited (RVUN) is rapidly increasing the number of power projects in the state and Chhabra Thermal Power Plant (CTPP) of 2320 MW capacity is one of its flagship projects.

In a thermal power station, several water flow circuits are involved which require permanent metering as well as temporary spot measurements. At Chhabra Power Plant, RVUN was looking for a solution for such flow metering requirements. They also required Flowmeters for the ETP.

Ability to handle the project on a turnkey basis and proven experience were the main criteria for the selection of the instrumentation partner. Based on these expectations, Adept was their obvious choice, considering our ability to provide not only the Flowmeters, but also Automation, RPCB & CPCB connectivity support and SCADA connectivity support.

Challenges

At CTPP, the requirement of Flowmeters existed in two areas, viz.

![]() Main Power Plant

Main Power Plant

![]() Effluent Treatment Plant (ETP)

Effluent Treatment Plant (ETP)

Main Power Plant

Thermal power stations generate electricity by heating water to generate steam, which in turn, drive turbines and generators. In this process, there are several flow circuits which require constant flow monitoring. This necessitates installing Flowmeters for permanent metering as well as for temporary spot measurements. Water flows at a very high speed through the pipelines of the power plant. This imposes limitations on the use of inline Fowmeters due to the possibility of leakages and also the inline device disturbs the flow and can cause pressure drops. Another challenge is posed by highly purified water being used in such plants to reduce corrosion. Purified water, due to absence of minerals, does not have electrical conductivity and thus eliminates the possibility of using electromagnetic Flowmeters.

Effluent Treatment Plant (ETP)

CTPP also required suitable Flowmeters for the measurement of flow at critical locations such as ETP, clear water line and horticulture water lines. Being a large power plant, high amount of effluents are generated during various processes which are treated through ETP for reuse or recycling of water. The flow of effluents and water requires to be carefully monitored at several steps in ETP. Accuracy of the flow data is highly important, which is required to be sent to RPCB & CPCB.

Solution

For Main Power Plant Water Metering

After thoroughly evaluating the requirement of flow metering at various stages at CTPP, we suggested a combination of non-contact, clamp-on, fixed type Ultrasonic and Electromagnetic Flowmeters. Purified water, due to absence of minerals, does not have electrical conductivity and thus eliminates the possibility of using electromagnetic Flowmeters.

This comprises 16 nos. Ultrasonic Flowmeters model 6710 and 4 nos. Full-bore Electromagnetic Flowmeters model 6410 of various sizes ranging from 50 mm to 700 mm.

The project was handled on a turnkey basis comprising supply of Flowmeters, installation & commissioning, and providing after-sales service for one year. The complete scope also included supply of other required material such as cables, JBs, field canopy, as well as carrying out allied work such as laying cables for a stretch of 12 km, excavation and civil work.

Typical applications of UFM 6710 Clamp-on Flowmeters

![]() Feed water, cooling water and condensate flow metering

Feed water, cooling water and condensate flow metering

![]() Pump, valve and inline Flowmeter performance verification

Pump, valve and inline Flowmeter performance verification

![]() Leakage and blockage detection

Leakage and blockage detection

![]() Metering of fly ash disposal lines

Metering of fly ash disposal lines

![]() Heavy fuel oil metering

Heavy fuel oil metering

![]() Hot well make-up line

Hot well make-up line

![]() Hot well make-up discharge line

Hot well make-up discharge line

![]() Make-up line of DM CW overhead panel

Make-up line of DM CW overhead panel

![]() DM water transfer pumps at discharge line

DM water transfer pumps at discharge line

![]() Boiler feed pumps at discharge line

Boiler feed pumps at discharge line

![]() Forebay make-up line

Forebay make-up line

![]() Raw water pump house

Raw water pump house

For Effluent Treatment Plant (ETP)

We supplied, 4 nos. full bore type Electromagnetic Flowmeters model 6410 for ETP and horticulture lines. The work also involved providing complete automation solution and IoT gateway with the help of SCADA for ensuring connectivity to RPCB & CPCB.

Benefits

With the help of most relevant solutions from Adept, CTPP could fulfil their expectations while achieving several objectives.

Installing inline Flowmeter necessitates boring of pipe. This increases the possible risk of leakage of pipes due to high pressure in feed water pipes. Moreover, any inline device causes pressure drops and affects the flow of the medium. To avert these risks, Adept recommended Ultrasonic Flowmeters UFM 6710. The sensors of the UFM 6710 are clamped onto the outside of pipes and hence, there is no pressure drop and no risk of leakage at any time.

In order to avoid corrosion, feed water used in steam boilers of thermal power stations is highly purified. Due to its high purification level, it becomes an electrical insulator eliminating the possibility of measuring flow with electromagnetic meters. By employing ultrasonic technology to determine flow rates, the UFM 6710 clamp-on meters can measure the flow of liquids regardless of their electric conductivity.

The installation of inline Flowmeters requires pipes to be cut, which in turn, requires shutdown of single systems or sometimes the entire plant. As the sensors of the UFM 6710 Ultrasonic Flowmeters are clamped onto the outside of pipes, there is no need to cut them and therefore, no interruption of the flow.

The flexibility offered by our portable and fixed-installation Flowmeters enables them to be used at different areas of a power station, for different liquids and on pipes of almost every common material and diameters from 10 mm to 4570 mm. Due to the high temperature resistance of our clamp-on sensors, Adept Flowmeters can also be used on pipes with temperatures of up to 250oC, which makes them suitable for use on hot water and condensate pipelines.

Due to the GSM connectivity and SCADA support, Adept Flowmeters can be easily integrated with the centralised system.

CTPP, Chhabra team of Rajasthan Rajya Vidyut Utpadan Nigam is happy with the performance of Flowmeters supplied by us and the support from our team during installation and commissioning.

View other case studies