Blogs

How Electromagnetic Flowmeter works

Working Principle : Electromagnetic Flowmeters are based on Faraday’s Law of Electromagnetic Induction. In an Electromagnetic Flowmeter, the magnetic field is generated by a set of coils. As the conductive liquid passes through the electromagnetic field, an electric voltage is induced in the liquid which is directly proportional to its […]

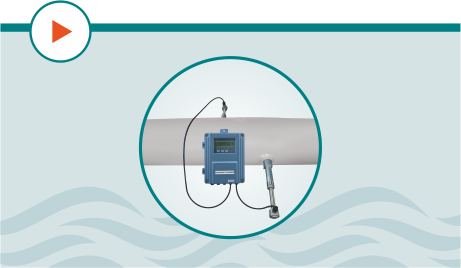

How Ultrasonic

Flowmeter works

Working Principle : The Transit Time Flowmeter utilises two transducers that function as both, ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe or inserted in the pipeline by using an isolating ball valve assembly at a specific distance from each other. Transit Time […]

5 things to remember while choosing an Electromagnetic Flowmeter

There are a variety of Flowmeters available to measure different types of fluids like liquid, gas, slurry, vapour, etc. The vital criterion for the selection of the right Flowmeter is to know its intended use – which application it is required for or what it is going to measure. An […]

Why modern Ultrasonic Water Meters are better than old mechanical water meter

By installing a water meter, you expect to know your water consumption periodically. Its precision is important as the water bill you pay is based on these readings. Also, periodically knowing the consumption helps you avoid wastage and control the consumption of this precious resource. Traditional water meters use mechanical […]

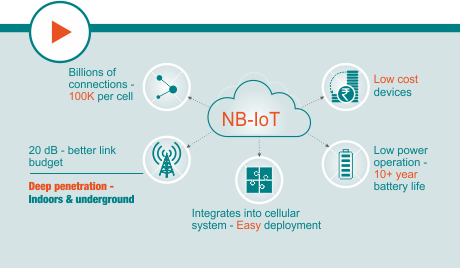

How NB-IoT is making inroads Into the LPWAN landscape

Providing a unique combination of long-range, low-power and low-cost advantages, LPWAN (Low Power Wide Area Networks) are poised to become the backbone of battery-operated IoT sensor networks across verticals. Nevertheless, not all LPWAN technologies are created equal, and there exists a persistent trade-off between Quality of Service (QoS) and battery […]

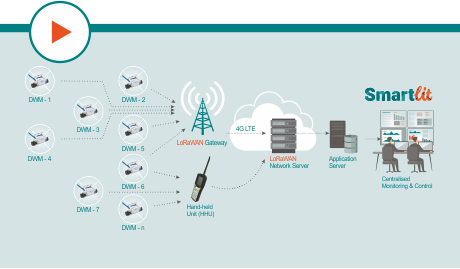

Why LoRaWAN is the preferred communication protocol for Smart Metering and Industry 4.0

The Fourth Industrial Revolution (Industry 4.0) is the automation of conventional manufacturing and industrial processes using modern smart technology. Large-scale machine-to-machine communication (M2M) and the Internet of Things (IoT) are integrated for increased automation, improved communication and self-monitoring due to the ability to analyse and diagnose issues without the need for human intervention. The SMART Sensors: It […]