Case study #109: National Physical Laboratory (NPL)

India’s premier research laboratory entrusts Adept with the responsibility of setting up Water Meter and Flowmeter Testing and Calibration facility

National Physical Laboratory (NPL) selected Adept to play a major role in this project due to our experience of more than 3 decades in Flowmeters manufacturing and calibration as well as our self-developed NABL accredited calibration facilities.

NPL also offers calibration and testing services, acting as an interface between all the calibrating and testing groups of CSIR-NPL with numerous customers from the industry, various laboratories and government organisations – locally and globally.

About the requirement

The Fluid Flow Measurement Standard Group of NPL wanted to revamp their Water Meter Testing and Calibration set-up and replace it with a state-of-the-art facility conforming to the global standards that befit an institute with NMI status in India.

The NPL invited bids from various laboratories, institutes and companies with proven expertise in designing and implementing such systems. Adept was awarded the contract after a thorough evaluation and comparison of various technical parameters of the proposed system vis-à-vis competitors. The competence acquired by Adept in Flowmeter manufacturing and calibration for over 3 decades, and establishing self-developed NABL accredited calibration facilities played a key role during the selection process.

Challenges

The existing set-up at NPL was very old and challenging to maintain mainly due to non-availability of spares and absence of thorough documentation. Various modules were lacking integration and centralised control was not possible. Being an old generation technology, it was also lacking in delivering the performance that is necessary to address the needs of today’s industries. There were a few more drawbacks of the existing set-up.

![]() It was a fully automatic system but the automation was highly complex making it difficult to monitor and maintain

It was a fully automatic system but the automation was highly complex making it difficult to monitor and maintain

![]() Only pulse output type Flowmeters could be calibrated

Only pulse output type Flowmeters could be calibrated

![]() Straight length requirements were not met for Flowmeters of different sizes particularly when reducers were used

Straight length requirements were not met for Flowmeters of different sizes particularly when reducers were used

![]() It was a highly complicated system, making it difficult to operate and maintain

It was a highly complicated system, making it difficult to operate and maintain

![]() No electronics or instrumentation engineer was available to maintain the set-up

No electronics or instrumentation engineer was available to maintain the set-up

![]() Weighing systems were not interconnected

Weighing systems were not interconnected

![]() Large volume of water was required to be collected

Large volume of water was required to be collected

![]() Being a load cell based weighing system, uncertainty was higher leading to less accuracy of readings

Being a load cell based weighing system, uncertainty was higher leading to less accuracy of readings

Solution

Before undertaking the design of the new facility, the Engineering Solutions team of Adept thoroughly inspected the existing set-up and interacted with the NPL team to understand their exact requirements and expectations from the new system.

Knowing this, Adept decided on the gravimetric-based flow calibration facility employing the latest in instrumentation and control. Adept successfully installed and commissioned it while adhering to proven and best engineering practices.

After installation, the NPL team closely monitored various trials, which were successfully concluded to their utmost satisfaction. The key features of the system are:

![]() Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

![]() Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

![]() High performance weighing systems with exceptional repeatability and linearity

High performance weighing systems with exceptional repeatability and linearity

![]() Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

![]() Pumps with VFDs for precision flow control and energy saving

Pumps with VFDs for precision flow control and energy saving

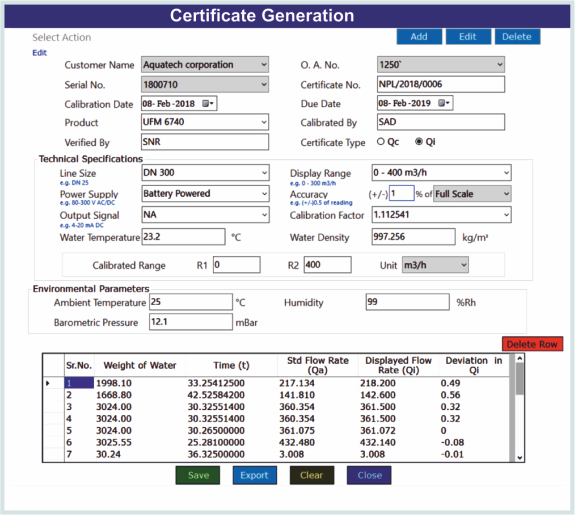

![]() Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

![]() Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

![]() On-screen graphics to display the instantaneous status of all the field devices

On-screen graphics to display the instantaneous status of all the field devices

![]() Inbuilt operational safety features

Inbuilt operational safety features

NPL, Delhi – The apex Indian institute selected Adept to design and deliver a new Water Meter Testing and Calibration facility.

Benefits

NPL is experiencing multiple benefits while using the new facility delivered by Adept. Significant among them are:

![]() Capability to calibrate Flowmeters of 12 different sizes from DN 15 to DN 200, all under a single roof

Capability to calibrate Flowmeters of 12 different sizes from DN 15 to DN 200, all under a single roof

![]() The uncertainty in Flowmeter calibration for totalized mass and totalized volume parameters is in the range of 0.01-0.02% (at k=2) whereas for mass flow rate and volume flow rate parameters is in the range of 0.03-0.05% (at k=2) which are at par with the international level

The uncertainty in Flowmeter calibration for totalized mass and totalized volume parameters is in the range of 0.01-0.02% (at k=2) whereas for mass flow rate and volume flow rate parameters is in the range of 0.03-0.05% (at k=2) which are at par with the international level

![]() Inbuilt mathematical and statistical functions completely eliminate human error

Inbuilt mathematical and statistical functions completely eliminate human error

![]() Efficient and reliable operations

Efficient and reliable operations

![]() Efficient and reliable operations

Efficient and reliable operations

![]() Operation and monitoring from the comfort of the centralised control room

Operation and monitoring from the comfort of the centralised control room

![]() Password protection to ensure only authorised person/s can access the system

Password protection to ensure only authorised person/s can access the system

This prestigious installation of Flowmeter Testing and Calibration facility at NPL, Delhi is a further attestation of our quality, reliability and capability in the flow instrumentation business.

View other case studies