Case study #102: Palsana Enviro Protection Limited (PEPL)

Asia’s largest Common Effluent Treatment Plant (CETP) trusts

Adept’s expertise in Water Network Automation

Automation with SCADA & GPRS Connectivity ensures real-time data collection without human intervention.

Palsana Enviro Protection Limited (PEPL) in Gujarat is one such company promoted by a cluster of textile processing industries for setting up of a Common Effluent Treatment Plant (CETP) for conveyance, treatment and disposal of waste water generated from the industries.

All members are textile dyeing and printing units located in and around Vareli, Kadodara, Tantithaiya and Jolwa in the Surat district. These industries are located in an area of approximately 100 sq. km. radius. Today, PEPL plant capacity is 150 MLD with recycling facility of 50 MLD, which makes it Asia’s largest CETP and the world’s largest textile- based Common Effluent Treatment Plant.

Challenges

![]() At PEPL, effluent is received from nearly 120 ETPs of different industries spread over an area of 100 sq. km radius. Effluent discharge at each of these locations is required to be monitored continuously. It also requires to monitor treated water discharge from ETP along with the distribution of treated water to various industries.

At PEPL, effluent is received from nearly 120 ETPs of different industries spread over an area of 100 sq. km radius. Effluent discharge at each of these locations is required to be monitored continuously. It also requires to monitor treated water discharge from ETP along with the distribution of treated water to various industries.

![]() PEPL operators have to be continuously in touch with other operators at each ETP for collecting information on the water status.

PEPL operators have to be continuously in touch with other operators at each ETP for collecting information on the water status.

![]() Additionally, water consumption of different ETPs is required to be monitored, for which readings have to be obtained from each ETP at the takeover point through Flowmeters installed at their end.

Additionally, water consumption of different ETPs is required to be monitored, for which readings have to be obtained from each ETP at the takeover point through Flowmeters installed at their end.

![]() Operators have to travel for collecting data from each Flowmeter. This was not only tedious but a highly time-consuming job involving several man-hours.

Operators have to travel for collecting data from each Flowmeter. This was not only tedious but a highly time-consuming job involving several man-hours.

Solution

Adept team carried out a detailed investigation about various requirements of PEPL and the challenges posed. Through interactions with various stakeholders, Adept has recommended an automation solution which was economical, yet highly reliable and efficient.

![]() The Adept solution includes GPRS type of SCADA System which is capable of sending all the information from different locations using cloud facility.

The Adept solution includes GPRS type of SCADA System which is capable of sending all the information from different locations using cloud facility.

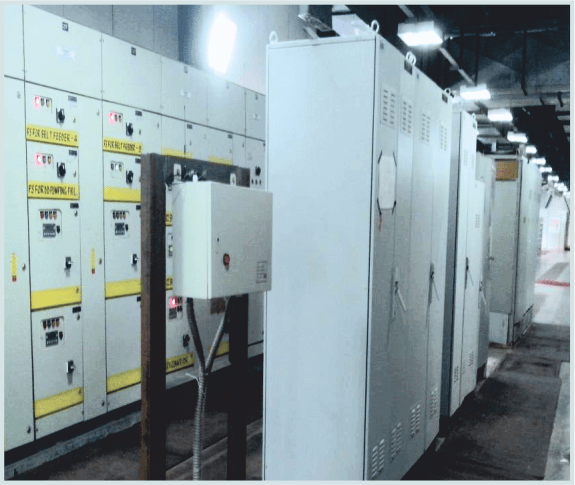

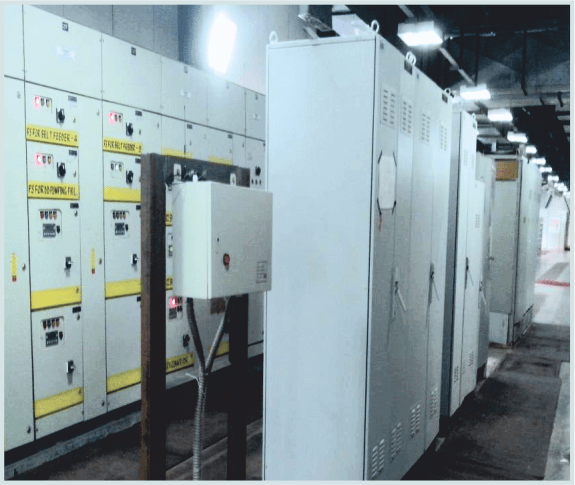

![]() Specially designed Control Panels are provided for all Flowmeters which are capable of sending the process values through a wireless network without requiring any human interference.

Specially designed Control Panels are provided for all Flowmeters which are capable of sending the process values through a wireless network without requiring any human interference.

![]() Inbuilt data storage function allows retrieval of data, even after several years.

Inbuilt data storage function allows retrieval of data, even after several years.

![]() Provided SCADA software which is extremely user-friendly and even an untrained person can retrieve all the process parameters

Provided SCADA software which is extremely user-friendly and even an untrained person can retrieve all the process parameters

Benefits

![]() No need anymore to travel long distances for collection of the data.

No need anymore to travel long distances for collection of the data.

![]() Data storage and retrieval is possible even after a few years which can be used for effective planning of the future needs.

Data storage and retrieval is possible even after a few years which can be used for effective planning of the future needs.

![]() Ease of report generation by using customised SCADA software.

Ease of report generation by using customised SCADA software.

![]() Remote troubleshooting facility with 24×7 software support.

Remote troubleshooting facility with 24×7 software support.

![]() Accurate and real-time data availability.

Accurate and real-time data availability.

Components of SCADA

![]() GPRS Modem

GPRS Modem

![]() SCADA Server

SCADA Server

![]() Remote Terminal Units (RTUs)

Remote Terminal Units (RTUs)

![]() Web Application

Web Application

Features of SCADA

![]() Dynamic Process Graphic

Dynamic Process Graphic

![]() Script for Logic Development

Script for Logic Development

![]() Device Connectivity

Device Connectivity

![]() Recipe Management

Recipe Management

![]() Database Connectivity & Security

Database Connectivity & Security

![]() Alarms

Alarms

![]() Real Time and Historical Trending

Real Time and Historical Trending

Collective treatment at a centralised facility, known as the CETP is considered as a viable treatment solution to overcome the constraints associated with effluent treatment in small and medium enterprises.

Palsana Enviro Protection Limited (PEPL) in Gujarat is one such company promoted by a cluster of textile processing industries for setting up of a Common Effluent Treatment Plant (CETP) for conveyance, treatment and disposal of waste water generated from the industries.

All members are textile dyeing and printing units located in and around Vareli, Kadodara, Tantithaiya and Jolwa in the Surat district. These industries are located in an area of approximately 100 sq. km. radius. Today, PEPL plant capacity is 150 MLD with recycling facility of 50 MLD, which makes it Asia’s largest CETP and the world’s largest textile- based Common Effluent Treatment Plant.

Challenges

![]() At PEPL, effluent is received from nearly 120 ETPs of different industries spread over an area of 100 sq. km radius. Effluent discharge at each of these locations is required to be monitored continuously. It also requires to monitor treated water discharge from ETP along with the distribution of treated water to various industries.

At PEPL, effluent is received from nearly 120 ETPs of different industries spread over an area of 100 sq. km radius. Effluent discharge at each of these locations is required to be monitored continuously. It also requires to monitor treated water discharge from ETP along with the distribution of treated water to various industries.

![]() PEPL operators have to be continuously in touch with other operators at each ETP for collecting information on the water status.

PEPL operators have to be continuously in touch with other operators at each ETP for collecting information on the water status.

![]() Additionally, water consumption of different ETPs is required to be monitored, for which readings have to be obtained from each ETP at the takeover point through Flowmeters installed at their end.

Additionally, water consumption of different ETPs is required to be monitored, for which readings have to be obtained from each ETP at the takeover point through Flowmeters installed at their end.

![]() Operators have to travel for collecting data from each Flowmeter. This was not only tedious but a highly time-consuming job involving several man-hours.

Operators have to travel for collecting data from each Flowmeter. This was not only tedious but a highly time-consuming job involving several man-hours.

Solution

Adept team carried out a detailed investigation about various requirements of PEPL and the challenges posed. Through interactions with various stakeholders, Adept has recommended an automation solution which was economical, yet highly reliable and efficient.

![]() The Adept solution includes GPRS type of SCADA System which is capable of sending all the information from different locations using cloud facility.

The Adept solution includes GPRS type of SCADA System which is capable of sending all the information from different locations using cloud facility.

![]() Specially designed Control Panels are provided for all Flowmeters which are capable of sending the process values through a wireless network without requiring any human interference.

Specially designed Control Panels are provided for all Flowmeters which are capable of sending the process values through a wireless network without requiring any human interference.

![]() Inbuilt data storage function allows retrieval of data, even after several years.

Inbuilt data storage function allows retrieval of data, even after several years.

![]() Provided SCADA software which is extremely user-friendly and even an untrained person can retrieve all the process parameters

Provided SCADA software which is extremely user-friendly and even an untrained person can retrieve all the process parameters

Benefits

![]() No need anymore to travel long distances for collection of the data.

No need anymore to travel long distances for collection of the data.

![]() Data storage and retrieval is possible even after a few years which can be used for effective planning of the future needs.

Data storage and retrieval is possible even after a few years which can be used for effective planning of the future needs.

![]() Ease of report generation by using customised SCADA software.

Ease of report generation by using customised SCADA software.

![]() Remote troubleshooting facility with 24×7 software support.

Remote troubleshooting facility with 24×7 software support.

![]() Accurate and real-time data availability.

Accurate and real-time data availability.

Components of SCADA

![]() GPRS Modem

GPRS Modem

![]() SCADA Server

SCADA Server

![]() Remote Terminal Units (RTUs)

Remote Terminal Units (RTUs)

![]() Web Application

Web Application

Features of SCADA

![]() Dynamic Process Graphic

Dynamic Process Graphic

![]() Script for Logic Development

Script for Logic Development

![]() Device Connectivity

Device Connectivity

![]() Recipe Management

Recipe Management

![]() Database Connectivity & Security

Database Connectivity & Security

![]() Alarms

Alarms

![]() Real Time and Historical Trending

Real Time and Historical Trending

Satisfied with the performance of our SCADA solution for automation. PEPL has plased further orders on us for their new requirments.

View other case studies