Case study #101: JSW Steel

Adept helps India’s leading steel manufacturer to exercise precise control

on its water network, reduce human efforts and achieve automation

Flowmeters Integration for Data Acquisition and Monitoring from Industrial Water Treatment Process at JSW, Vijayanagar Works

The plant operation requires several million litres of water everyday which is sourced from nearby dams. Multiple sourcing points and a large water network requires constant monitoring of raw water parameters as well consumption. This was posing several challenges. Though JSW installed Flowmeters at critical locations, it involved people walking down several kilometers to obtain readings and exercise control. Particularly, this was tedious in the rainy season

The JSW team was looking for a competent partner who could develop a customised solution to overcome these challenges. Knowing the reputation of Adept as a leading manufacturer of Flowmeters who possesses the ability to develop integrated systems for monitoring and control, JSW turned to Adept.

Challenges

The entire water management operations necessitated various following tasks to be carried out on a daily basis.

![]() The operation of the water treatment plant is being supervised by 3 operators in shifts. It is essential to constantly monitor water parameters and distribution of treated water to the entire JSW plant.

The operation of the water treatment plant is being supervised by 3 operators in shifts. It is essential to constantly monitor water parameters and distribution of treated water to the entire JSW plant.

![]() The JSW Steel team had to be constantly in touch with the Pump House Operators at sources for obtaining information on the raw water pumping status

The JSW Steel team had to be constantly in touch with the Pump House Operators at sources for obtaining information on the raw water pumping status

![]() The operators of Emergency Water Pumping Stations were required to be regularly contacted for maintaining the sump level.

The operators of Emergency Water Pumping Stations were required to be regularly contacted for maintaining the sump level.

![]() Additionally, water consumption of different shops requires to be monitored periodically. For this, Flowmeters readings have to be obtained from each shop at the takeover point.

Additionally, water consumption of different shops requires to be monitored periodically. For this, Flowmeters readings have to be obtained from each shop at the takeover point.

This entire operation involved two operators every time travelling for a long time. This was required for obtaining readings and various other process values from 150 Flowmeters installed at different locations. It was a very tedious task, particularly in the rainy season, and was becoming unmanageable day by day.

Solution

After a careful study of the entire operations by the expert team of Adept, we recommended JSW Steel with a system comprising the following.

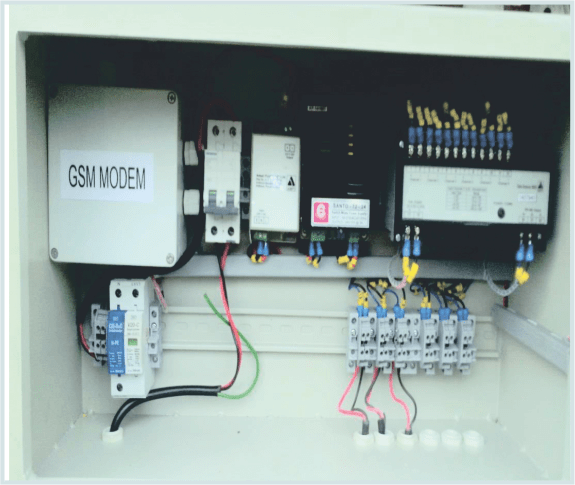

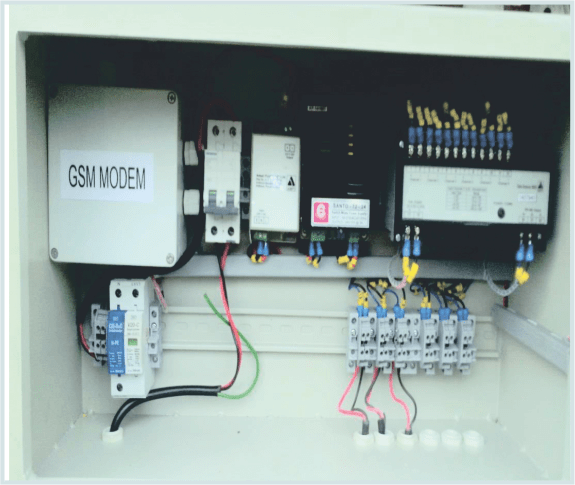

GSM type of SCADA System which is capable of sending all information from remote locations using SMS facility (completely wire-free).

Housing and Panel for each Flowmeter and other process instruments which are capable of sending process values automatically through a wireless network, avoiding human interference.

Data storage function for future reference, allowing data retrieval even after several years.

Adept helps India’s leading steel manufacturer to exercise precise control on its water network, reduce human efforts and achieve automation.

![]()

The JSW Steel team is now empowered to exercise precise control on its water network and that too in real-time besides saving considerable human efforts. The entire team at JSW Steel is extremely happy with the customised solution developed by Adept and its trouble-free performance.

Benefits

![]() Data Collection & Report

Data Collection & Report

![]() Ease of data collection – became very easy, more precise and faster.

Ease of data collection – became very easy, more precise and faster.

![]() Real-time data availability allows to exercise highly precise control on operations.

Real-time data availability allows to exercise highly precise control on operations.

![]() Quick report generation using customised SCADA software.

Quick report generation using customised SCADA software.

![]() Custom-designed SCADA software is extremely user- friendly. Even an untrained person can retrieve all the process parameters quickly and easily

Custom-designed SCADA software is extremely user- friendly. Even an untrained person can retrieve all the process parameters quickly and easily

![]() Remote troubleshooting is possible with round the clock software support.

Remote troubleshooting is possible with round the clock software support.

![]() Easy storage and retrieval of data – highly robust and reliable MIS.

Easy storage and retrieval of data – highly robust and reliable MIS.

![]() Daily travelling by each operator just for collecting data is now completely stopped

Daily travelling by each operator just for collecting data is now completely stopped

![]() Drastic reduction in manual efforts – saves time, efforts, costs

Drastic reduction in manual efforts – saves time, efforts, costs

JSW Group is now India’s leading manufacturer of value-added and high-end steel. JSW Steel has plants in Karnataka, Tamil Nadu and Maharashtra and has a total capacity of 18 million tons per annum (MTPA). One of its major plants is located at Toranagallu village in the Bellary-Hospet iron ore belt known as Vijayanagar works. This plant of JSW is the world’s sixth largest steel plant.

The plant operation requires several million litres of water everyday which is sourced from nearby dams. Multiple sourcing points and a large water network requires constant monitoring of raw water parameters as well consumption. This was posing several challenges. Though JSW installed Flowmeters at critical locations, it involved people walking down several kilometers to obtain readings and exercise control. Particularly, this was tedious in the rainy season

The JSW team was looking for a competent partner who could develop a customised solution to overcome these challenges. Knowing the reputation of Adept as a leading manufacturer of Flowmeters who possesses the ability to develop integrated systems for monitoring and control, JSW turned to Adept.

Challenges

The entire water management operations necessitated various following tasks to be carried out on a daily basis.

![]() The operation of the water treatment plant is being supervised by 3 operators in shifts. It is essential to constantly monitor water parameters and distribution of treated water to the entire JSW plant.

The operation of the water treatment plant is being supervised by 3 operators in shifts. It is essential to constantly monitor water parameters and distribution of treated water to the entire JSW plant.

![]() The JSW Steel team had to be constantly in touch with the Pump House Operators at sources for obtaining information on the raw water pumping status

The JSW Steel team had to be constantly in touch with the Pump House Operators at sources for obtaining information on the raw water pumping status

![]() The operators of Emergency Water Pumping Stations were required to be regularly contacted for maintaining the sump level.

The operators of Emergency Water Pumping Stations were required to be regularly contacted for maintaining the sump level.

![]() Additionally, water consumption of different shops requires to be monitored periodically. For this, Flowmeters readings have to be obtained from each shop at the takeover point.

Additionally, water consumption of different shops requires to be monitored periodically. For this, Flowmeters readings have to be obtained from each shop at the takeover point.

This entire operation involved two operators every time travelling for a long time. This was required for obtaining readings and various other process values from 150 Flowmeters installed at different locations. It was a very tedious task, particularly in the rainy season, and was becoming unmanageable day by day.

Solution

After a careful study of the entire operations by the expert team of Adept, we recommended JSW Steel with a system comprising the following.

GSM type of SCADA System which is capable of sending all information from remote locations using SMS facility (completely wire-free).

Housing and Panel for each Flowmeter and other process instruments which are capable of sending process values automatically through a wireless network, avoiding human interference.

Data storage function for future reference, allowing data retrieval even after several years.

Adept helps India’s leading steel manufacturer to exercise precise control on its water network, reduce human efforts and achieve automation.

![]()

The JSW Steel team is now empowered to exercise precise control on its water network and that too in real-time besides saving considerable human efforts. The entire team at JSW Steel is extremely happy with the customised solution developed by Adept and its trouble-free performance.

Benefits

![]() Data Collection & Report

Data Collection & Report

![]() Ease of data collection – became very easy, more precise and faster.

Ease of data collection – became very easy, more precise and faster.

![]() Real-time data availability allows to exercise highly precise control on operations.

Real-time data availability allows to exercise highly precise control on operations.

![]() Quick report generation using customised SCADA software.

Quick report generation using customised SCADA software.

![]() Custom-designed SCADA software is extremely user- friendly. Even an untrained person can retrieve all the process parameters quickly and easily

Custom-designed SCADA software is extremely user- friendly. Even an untrained person can retrieve all the process parameters quickly and easily

![]() Remote troubleshooting is possible with round the clock software support.

Remote troubleshooting is possible with round the clock software support.

![]() Easy storage and retrieval of data – highly robust and reliable MIS.

Easy storage and retrieval of data – highly robust and reliable MIS.

![]() Daily travelling by each operator just for collecting data is now completely stopped

Daily travelling by each operator just for collecting data is now completely stopped

![]() Drastic reduction in manual efforts – saves time, efforts, costs

Drastic reduction in manual efforts – saves time, efforts, costs

The JSW Steel team is now empowered to exercise precise control on its water network and that too in real-time besides saving considerable human efforts. The entire team at JSW Steel is extremely happy with the customised solution developed by Adept and its trouble-free performance.

View other case studies