Case study #110: Mokhabardi Lift Irrigation Project, Maharashtra

A major lift irrigation project in the Vidarbha region required routine measurement of water discharge from the reservoir to the main canal to achieve equitable distribution

Adept has supplied three MagFlow 6410 having 2700 mm dia., possibly the largest Flowmeters in India.

The project involves the 11.35 km long Gosi Khurd Dam along with the network of water canals including the 99 km long right bank canal, 22.93 km long left bank canal and lifting stations at Akot, Ambhora, Mokhabardi, Nerla and Tekepar. The project aims to irrigate approx. 0.25 million hectares of land besides providing water to industries and drinking water schemes.

Mokhabardi Lift Irrigation Project is situated near the Kinhala village in Nagpur District. At this project, water is lifted from the reservoir by large pumps and is then distributed through gravity-fed canals in different directions to irrigate agricultural land and provide drinking water to various villages.

About the requirement

Part of the work for the Mokhabardi Lift Irrigation Project was awarded to a leading EPC company by Vidarbha Irrigation Development Corporation (VIDC). A large pump house consisting of 16 pumps has been already constructed at the project site to lift and distribute the water through a canal. Water from the reservoir is pumped into three different, large diameter pipelines which are at a much higher level than the reservoir. Water from these three pipelines is subsequently released into a canal for further transportation and distribution.

In order to ensure that the right amount of water got released periodically, it was important to measure it before releasing it into the canal. For this, Flowmeters having a diameter of 2700 mm were to be fitted in each pipeline. The customer proposed using Electromagnetic Flowmeters, so that the amount of water could be measured precisely before discharge into the canal. The customer also required telemetry solutions for remote monitoring.

Challenges

Knowing our expertise in the Flow Instrumentation business, the customer team approached us for the right solution. After evaluating our credentials and the capacity to manufacture large size Flowmeters, they have awarded us the contract for manufacturing, calibrating, installation and commissioning of three Electromagnetic Flowmeters of 2700 mm diameterinty was higher leading to less accuracy of readings

![]() Largest diameter Flowmeters ever manufactured in India

Largest diameter Flowmeters ever manufactured in India

Adept has a vast experience in manufacturing large diameter Flowmeters which are usually up to 2000 mm diameter. For manufacturing Flowmeters of 2700 mm dia., we developed special fixtures which would ensure a high level of precision in manufacturing.

![]() Calibration of Flowmeters was a great challenge

Calibration of Flowmeters was a great challenge

The customer insisted on Flowmeters that were fully calibrated and certified by a reputed institute. For calibrating such a large diameter Flowmeter, the onlyset-up available in India is at FCRI (Fluid Control Research Institute), at Palakkad in Kerala which is the government owned, premier calibration laboratory in India. Thus, after manufacturing and ensuring complete precision, the Flowmeters were taken to Palakkad where they passed the calibration test in the first go itself.

![]() Telemetry features

Telemetry features

We have supplied all the three Flowmeters withGSM/GPRS enabled telemetry solution. With this feature, it is possible to get real-time data from a remote location without travelling to far off distances.

![]() Installation and commissioning

Installation and commissioning

Considering the remote location of the project and the tough terrain, the installation and commissioning were truly challenging. Our team of experts carried out the job in just under one week with the help of crawler cranes for lifting and placing the Flowmeters. The entire project was commissioned in the year 2019 and the users at the Mokhabardi Lift Irrigation Project are happy with the performance of Adept Flowmeters.

Solution

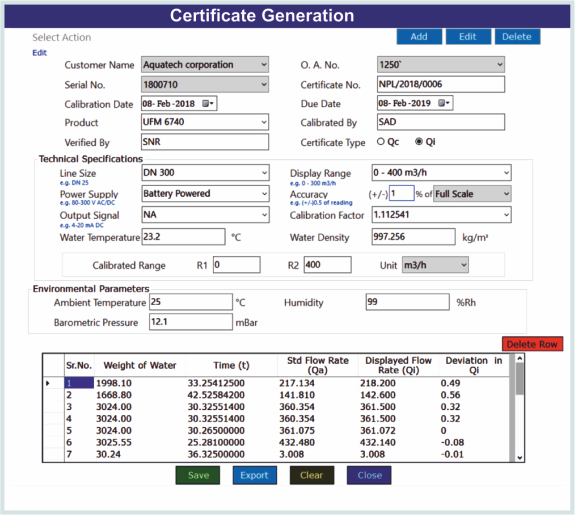

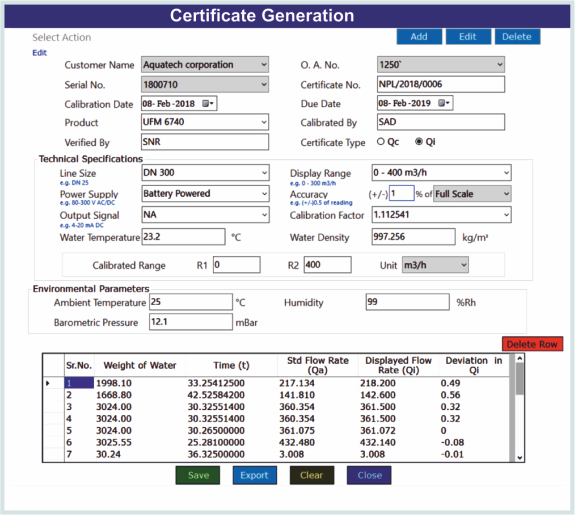

Before undertaking the design of the new facility, the Engineering Solutions team of Adept thoroughly inspected the existing set-up and interacted with the NPL team to understand their exact requirements and expectations from the new system.

Knowing this, Adept decided on the gravimetric-based flow calibration facility employing the latest in instrumentation and control. Adept successfully installed and commissioned it while adhering to proven and best engineering practices.

After installation, the NPL team closely monitored various trials, which were successfully concluded to their utmost satisfaction. The key features of the system are:

![]() Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

![]() Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

![]() High performance weighing systems with exceptional repeatability and linearity

High performance weighing systems with exceptional repeatability and linearity

![]() Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

![]() Pumps with VFDs for precision flow control and energy saving

Pumps with VFDs for precision flow control and energy saving

![]() Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

![]() Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

![]() On-screen graphics to display the instantaneous status of all the field devices

On-screen graphics to display the instantaneous status of all the field devices

![]() Inbuilt operational safety features

Inbuilt operational safety features

In order to ensure that the right amount of water got released periodically, it was important to measure it before releasing it into the canal. For this, Flowmeters with a diameter of 2700 mm each were to be fitted in each pipeline.

Adept shouldered turnkey project responsibility consisting of design, supply, testing at FCRI, installation, commissioning and providing of service support.

Benefits

![]() Reliable technology

Reliable technology

Adept has installed over 40,000 Flowmeters. Several of them are large sized and are operational in various critical industries such as steel and thermal power plants. This vast experience was leveraged while manufacturing Flowmeters for this project with an assurance of flawless performance.

![]() On-time delivery

On-time delivery

With our large, in-house manufacturing capability and experienced project management team, we havecompleted manufacturing, despatch, erection & commissioning of these Flowmeters well ahead of schedule.

![]() Ease of control and monitoring

Ease of control and monitoring

The GSM/GPRS Telemetry feature inbuilt in these Flowmeters allows flow monitoring even from a remote location and reduces the hassle of travelling to far off locations.

![]() Assurance of post-sales service

Assurance of post-sales service

Adept has a large, well-trained team for post-sales support which assures quick resolution of issues in case they arise.

The Gosi Khurd Irrigation Project is one of the major irrigation projects in Maharashtra in the Bhandara district on the river Wainganga. It is one of the largest irrigation projects in the Vidarbha region and has been declared as a National Irrigation Project by the Government of India.

The project involves the 11.35 km long Gosi Khurd Dam along with the network of water canals including the 99 km long right bank canal, 22.93 km long left bank canal and lifting stations at Akot, Ambhora, Mokhabardi, Nerla and Tekepar. The project aims to irrigate approx. 0.25 million hectares of land besides providing water to industries and drinking water schemes.

Mokhabardi Lift Irrigation Project is situated near the Kinhala village in Nagpur District. At this project, water is lifted from the reservoir by large pumps and is then distributed through gravity-fed canals in different directions to irrigate agricultural land and provide drinking water to various villages.

About the requirement

Part of the work for the Mokhabardi Lift Irrigation Project was awarded to a leading EPC company by Vidarbha Irrigation Development Corporation (VIDC). A large pump house consisting of 16 pumps has been already constructed at the project site to lift and distribute the water through a canal. Water from the reservoir is pumped into three different, large diameter pipelines which are at a much higher level than the reservoir. Water from these three pipelines is subsequently released into a canal for further transportation and distribution.

In order to ensure that the right amount of water got released periodically, it was important to measure it before releasing it into the canal. For this, Flowmeters having a diameter of 2700 mm were to be fitted in each pipeline. The customer proposed using Electromagnetic Flowmeters, so that the amount of water could be measured precisely before discharge into the canal. The customer also required telemetry solutions for remote monitoring.

Challenges

Knowing our expertise in the Flow Instrumentation business, the customer team approached us for the right solution. After evaluating our credentials and the capacity to manufacture large size Flowmeters, they have awarded us the contract for manufacturing, calibrating, installation and commissioning of three Electromagnetic Flowmeters of 2700 mm diameterinty was higher leading to less accuracy of readings

![]() Largest diameter Flowmeters ever manufactured in India

Largest diameter Flowmeters ever manufactured in India

Adept has a vast experience in manufacturing large diameter Flowmeters which are usually up to 2000 mm diameter. For manufacturing Flowmeters of 2700 mm dia., we developed special fixtures which would ensure a high level of precision in manufacturing.

![]() Calibration of Flowmeters was a great challenge

Calibration of Flowmeters was a great challenge

The customer insisted on Flowmeters that were fully calibrated and certified by a reputed institute. For calibrating such a large diameter Flowmeter, the onlyset-up available in India is at FCRI (Fluid Control Research Institute), at Palakkad in Kerala which is the government owned, premier calibration laboratory in India. Thus, after manufacturing and ensuring complete precision, the Flowmeters were taken to Palakkad where they passed the calibration test in the first go itself.

![]() Telemetry features

Telemetry features

We have supplied all the three Flowmeters with

GSM/GPRS enabled telemetry solution. With this feature, it is possible to get real-time data from a remote location without travelling to far off distances.

![]() Installation and commissioning

Installation and commissioning

Considering the remote location of the project and the tough terrain, the installation and commissioning were truly challenging. Our team of experts carried out the job in just under one week with the help of crawler cranes for lifting and placing the Flowmeters. The entire project was commissioned in the year 2019 and the users at the Mokhabardi Lift Irrigation Project are happy with the performance of Adept Flowmeters.

Solution

Before undertaking the design of the new facility, the Engineering Solutions team of Adept thoroughly inspected the existing set-up and interacted with the NPL team to understand their exact requirements and expectations from the new system.

Knowing this, Adept decided on the gravimetric-based flow calibration facility employing the latest in instrumentation and control. Adept successfully installed and commissioned it while adhering to proven and best engineering practices.

After installation, the NPL team closely monitored various trials, which were successfully concluded to their utmost satisfaction.

The key features of the system are:

![]() Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

Dedicated pipelines for five Flowmeter sizes from DN 25 to DN 200

![]() Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

Provision for seven intermediate pipelines for Flowmeter sizes DN 15 onwards

![]() High performance weighing systems with exceptional repeatability and linearity

High performance weighing systems with exceptional repeatability and linearity

![]() Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

Diverter, fishtail and nozzle subsystems to ensure extremely low diverter error

![]() Pumps with VFDs for precision flow control and energy saving

Pumps with VFDs for precision flow control and energy saving

![]() Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

Professional grade measurement instruments for accurate time totalising plus current and frequency averaging

![]() Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

Segregated systems for power and instrumentation & control to achieve highest levels of operational reliability

![]() On-screen graphics to display the instantaneous status of all the field devices

On-screen graphics to display the instantaneous status of all the field devices

![]() Inbuilt operational safety features

Inbuilt operational safety features

In order to ensure that the right amount of water got released periodically, it was important to measure it before releasing it into the canal. For this, Flowmeters with a diameter of 2700 mm each were to be fitted in each pipeline.

Adept shouldered turnkey project responsibility consisting of design, supply, testing at FCRI, installation, commissioning and providing of service support.

Benefits

![]() Reliable technology

Reliable technology

Adept has installed over 40,000 Flowmeters. Several of them are large sized and are operational in various critical industries such as steel and thermal power plants. This vast experience was leveraged while manufacturing Flowmeters for this project with an assurance of flawless performance.

![]() On-time delivery

On-time delivery

With our large, in-house manufacturing capability and experienced project management team, we havecompleted manufacturing, despatch, erection & commissioning of these Flowmeters well ahead of schedule.

![]() Ease of control and monitoring

Ease of control and monitoring

The GSM/GPRS Telemetry feature inbuilt in these Flowmeters allows flow monitoring even from a remote location and reduces the hassle of travelling to far off locations.

![]() Assurance of post-sales service

Assurance of post-sales service

Adept has a large, well-trained team for post-sales support which assures quick resolution of issues in case they arise.

Adept has successfully tackled the challenge of supplying these large Flowmeters of 2700 mm diameter and became the first Flowmeter manufacturer in India to develop such large-sized, completely calibrated Flowmeters with telemetry features.

View other case studies