Case study #111: Bhabha Atomic Research Centre

A premier nuclear research facility in India required a reliable flow measurement solution for its HVAC system.

Adept supplied over 70 Electromagnetic Flowmeters in the year 2002, which are demonstrating precise and trouble-free performance even in 2020!

BARC, Trombay has a nuclear reactor installed in its premises. Besides, there are several research laboratories and offices in the same premises which are air-conditioned. Considering the vast expanse of the premises, and the necessity for centralised air-conditioning, large cooling towers are installed to meet the requirements.

About the requirement

There are a number of offices and laboratories in the Trombay premises of BARC. For efficient cooling, HVAC systems including large cooling towers are installed at several places. The vast water network comprises several water circulation loops and at such installations, water flow is required to be measured at chiller outlets. A few of the facilities such as important laboratories, operate 24×7 and hence, a reliable instrument for water flow measurement is essential.

The pipe sizes in this water network vary from 50 mm to 300 mm. Considering the importance of ensuring that the right quantity of water was delivered from the chillers, high precision measuring instruments were essential. Reliability and trouble-free performance of flow measuring instruments over several years were other important requirements.

A few laboratories in the BARC and, in turn, HVAC systems operate continuously and hence, a reliable instrument for water flow measurement is essential.

Challenges

The team of BARC approached Adept in the year 2002 with the specific requirement for Electromagnetic Flowmeters. Precision in measuring the flow of water and long-term reliability of the instruments were the prime considerations. Besides, the capability to manufacture, deliver, install and commission over 70 Flowmeters in the stipulated time was a major criteria for the selection of the vendor.

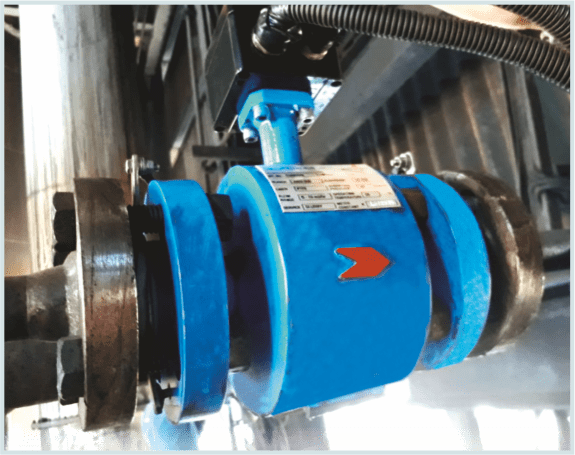

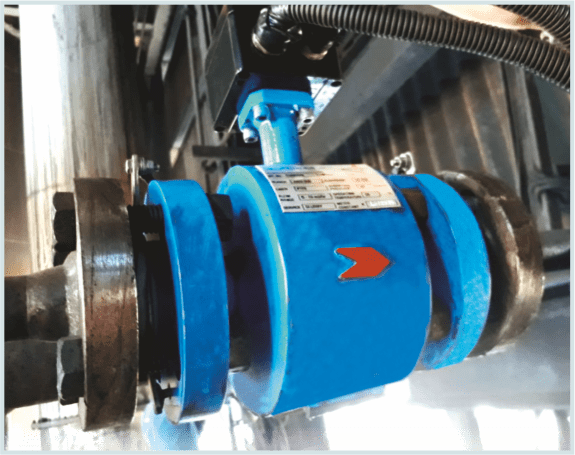

![]() Perfectly fitting Flowmeter solutions for the varied requirements of the plant

Perfectly fitting Flowmeter solutions for the varied requirements of the plant

As the water network is vast, line sizes vary from 50 mm to 300 mm diameter. We could easily meet these requirements due to our wide range. Also, considering the critical nature of the application, greatcare was taken while selecting the components of each Flowmeter, e.g. flange material, sensor lining, electrode material, coil housing, etc. The accessories, wherever required, were also selected carefully.

![]() Fully calibrated Flowmeters supplied ahead of schedule

Fully calibrated Flowmeters supplied ahead of schedule

The BARC team insisted that the Flowmeters were to be calibrated in their presence. We have a large, in-housecapacity to manufacture different types of Flowmeters along with an NABL accredited calibration setup. This has helped in easily meeting the demand and the deadline in spite of the large quantity of Flowmeters, with each one having different specifications.

![]() ‘Fit & forget’ − The unique benefit of our high quality Flowmeters

‘Fit & forget’ − The unique benefit of our high quality Flowmeters

Adept Flowmeters are built to perform and built to last.Our unique designs and advanced manufacturing practices ensure that our Flowmeters demonstrate trouble-free performance over a few decades.

![]() Installation and commissioning

Installation and commissioning

Considering the sensitive nature of the activities at BARC, the erection and commissioning were required to be performed in the shortest possible time with minimum interventions and with the help of less manpower. Our erection & commissioning team developed a project schedule with the help of the BARC team and completed the work exactly as per the schedule. All the Flowmeters are under AMC and being regularly checked for performance and calibrated on site. The entire project was commissioned in the year 2002 and the Flowmeters are performing well even today.

Solution

After a site visit to understand the dye manufacturing process and various critical application parameters, the Adept team recommended the use of its Electromagnetic Flowmeter model MagFlow 6410 with IP 68 class protection enclosure.

MagFlow 6410 is an advanced technology Flowmeter designed for demanding applications. It is capable of measuring the dye slurry within an accuracy level of ± 0.5% and provides pulse output of readings. Batching and dosing applications generally require a pulse output to measure volume of liquid over a certain period. Adept has supplied Electromagnetic Flowmeter model MagFlow 6410 suitable for 32 mm line size to Spectrum. These have been installed after the feed pump and before the drying chamber.

Display units of these Flowmeters are installed at a different location far away from the actual installation site. Due to this,it is possible for the operator to know the readings and monitor the flow from a remote location without physically going to the process station.

IP 68 protection class enclosure of MagFlow 6410 protectsit from external influences and the resultant damage due to conditions such as leakage.

Benefits

![]() High accuracy and reliable Flowmeters

High accuracy and reliable Flowmeters

This installation is among our first few large-scale projects. Right from the inception of the company, our emphasis has been on developing reliable technology and supplying high quality Flowmeters and the installation at BARC is a testimony to this.

![]() Timely delivery

Timely delivery

We have a large, in-house manufacturing capability and an experienced project management team which helped in completing the manufacturing, despatch and erection & commissioning of all the Flowmeters well ahead of the schedule.

![]() Assurance of post-sales service

Assurance of post-sales service

All these years, BARC has experienced efficient support from the team of service experts at Adept as well as trouble-free and precision performance of our Flowmeters.

BARC, Trombay has a nuclear reactor installed in its premises. Besides, there are several research laboratories and offices in the same premises which are air-conditioned. Considering the vast expanse of the premises, and the necessity for centralised air-conditioning, large cooling towers are installed to meet the requirements.

About the requirement

There are a number of offices and laboratories in the Trombay premises of BARC. For efficient cooling, HVAC systems including large cooling towers are installed at several places. The vast water network comprises several water circulation loops and at such installations, water flow is required to be measured at chiller outlets. A few of the facilities such as important laboratories, operate 24×7 and hence, a reliable instrument for water flow measurement is essential.

The pipe sizes in this water network vary from 50 mm to 300 mm. Considering the importance of ensuring that the right quantity of water was delivered from the chillers, high precision measuring instruments were essential. Reliability and trouble-free performance of flow measuring instruments over several years were other important requirements.

A few laboratories in the BARC and, in turn, HVAC systems operate continuously and hence, a reliable instrument for water flow measurement is essential.

Challenges

The team of BARC approached Adept in the year 2002 with the specific requirement for Electromagnetic Flowmeters. Precision in measuring the flow of water and long-term reliability of the instruments were the prime considerations. Besides, the capability to manufacture, deliver, install and commission over 70 Flowmeters in the stipulated time was a major criteria for the selection of the vendor.

![]() Perfectly fitting Flowmeter solutions for the varied requirements of the plant

Perfectly fitting Flowmeter solutions for the varied requirements of the plant

As the water network is vast, line sizes vary from 50 mm to 300 mm diameter. We could easily meet these requirements due to our wide range. Also, considering the critical nature of the application, greatcare was taken while selecting the components of each Flowmeter, e.g. flange material, sensor lining, electrode material, coil housing, etc. The accessories, wherever required, were also selected carefully.

![]() Fully calibrated Flowmeters supplied ahead of schedule

Fully calibrated Flowmeters supplied ahead of schedule

The BARC team insisted that the Flowmeters were to be calibrated in their presence. We have a large, in-house

capacity to manufacture different types of Flowmeters along with an NABL accredited calibration setup. This has helped in easily meeting the demand and the deadline in spite of the large quantity of Flowmeters, with each one having different specifications.

![]() ‘Fit & forget’ − The unique benefit of our high quality Flowmeters

‘Fit & forget’ − The unique benefit of our high quality Flowmeters

Adept Flowmeters are built to perform and built to last.

Our unique designs and advanced manufacturing practices ensure that our Flowmeters demonstrate trouble-free performance over a few decades.

![]() Installation and commissioning

Installation and commissioning

Considering the sensitive nature of the activities at BARC, the erection and commissioning were required to be performed in the shortest possible time with minimum interventions and with the help of less manpower. Our erection & commissioning team developed a project schedule with the help of the BARC team and completed the work exactly as per the schedule. All the Flowmeters are under AMC and being regularly checked for performance and calibrated on site. The entire project was commissioned in the year 2002 and the Flowmeters are performing well even today.

Solution

After a site visit to understand the dye manufacturing process and various critical application parameters, the Adept team recommended the use of its Electromagnetic Flowmeter model MagFlow 6410 with IP 68 class protection enclosure.

MagFlow 6410 is an advanced technology Flowmeter designed for demanding applications. It is capable of measuring the dye slurry within an accuracy level of ± 0.5% and provides pulse output of readings. Batching and dosing applications generally require a pulse output to measure volume of liquid over a certain period. Adept has supplied Electromagnetic Flowmeter model MagFlow 6410 suitable for 32 mm line size to Spectrum. These have been installed after the feed pump and before the drying chamber.

Display units of these Flowmeters are installed at a different location far away from the actual installation site. Due to this,

it is possible for the operator to know the readings and monitor the flow from a remote location without physically going to the process station.

IP 68 protection class enclosure of MagFlow 6410 protects

it from external influences and the resultant damage due to conditions such as leakage.

Benefits

![]() High accuracy and reliable Flowmeters

High accuracy and reliable Flowmeters

This installation is among our first few large-scale projects. Right from the inception of the company, our emphasis has been on developing reliable technology and supplying high quality Flowmeters and the installation at BARC is a testimony to this.

![]() Timely delivery

Timely delivery

We have a large, in-house manufacturing capability and an experienced project management team which helped in completing the manufacturing, despatch and erection & commissioning of all the Flowmeters well ahead of the schedule.

![]() Assurance of post-sales service

Assurance of post-sales service

All these years, BARC has experienced efficient support from the team of service experts at Adept as well as trouble-free and precision performance of our Flowmeters.

Quality is the hallmark of Adept Flowmeters. Like BARC, Adept has several installations

where our Flowmeters are performing day and night, without the slightest trouble, for nearly

two decades.

View other case studies